Machining Industry

One industry where the LubriWatch application is used effectively is the machining industry.

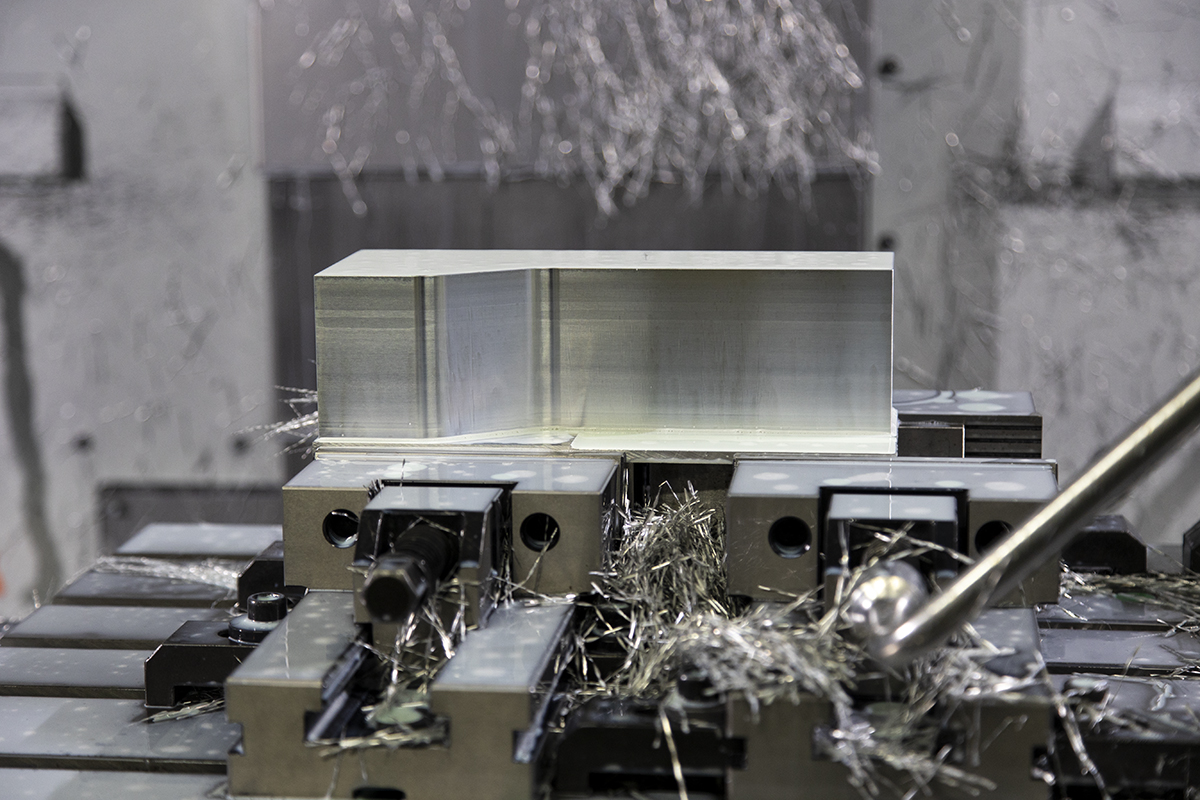

Metalworking is also known as machining. There are many different types of machining machines, such as milling machines, lathes, and tapping machines.

With these machines, you can perform various operations. Some examples include milling, tapping, drilling, sawing, filing, grinding, and planing. In addition to metal, machining operations can also be performed on wood and plastic.

Want to know more about measuring and entering values into the LubriWatch application? Request a demo.